The conversion of fermentable carbon sources into alcohol by yeast is a process that has been manipulated by humankind for centuries. During that time, we have realised that the choice of a particular carbon source, the water source, the strain of yeast and the way in which the parameters of the fermentation are controlled can have profound effects on the alcohol yield and other sensory characteristics of the final beverage.

Carbon Sources

The basis for fermentation is that all-important sugar source. Plant sources abundant with sucrose are ideal for the production of rum, fruits are well suited for wines, cider and brandies, and of course in the case of beers and whiskies, that foundation comes from the starches contained within cereal crops – with the help of enzymatic pre-hydrolysis. As our knowledge base grows, so do the options as to what and how you can ferment. Inexpensive sugar sources can be transformed into a variety of beverages even by just simply changing yeast strain. It is important when choosing a yeast strain, to remember that the types of sugar (maltose, maltotriose, glucose, sucrose, etc…) it can ferment will affect the final flavour, as do the specific secondary metabolites it produces.

Water source

Of course, with our knowledge of water chemistry, we no longer need to base the location of breweries or distilleries on water provenance – this may still be of importance however to the brand ethos. Water can often be forgotten but is hugely complex and is the largest constituent of a large variety of beverages. It consists of salts, ions and minerals, that must be analysed and tweaked during the brewing process to ensure the correct balance and alkalinity depending on the style of beverage you’re aiming to produce.

The terms ‘hardness’ (concentration of dissolved calcium and magnesium) and ‘alkalinity’ (the concentration of carbonate and bicarbonate) are two of the most important considerations.

Other considerations include: pH level; this is very important and actually affects every stage of the brewing/fermentation process. At each step, an optimum pH is required for enzymatic reactions and protein coagulation to occur, the presence of contaminants; iron, copper and chlorine can have negative effects on the final product such as off flavours including inky/metallic taste, haze formation, negative effects on the brewing yeast and the formation of other chlorophenols.

Yeast Nutrition

Sugar wash fermentations in particular, lack the nutrients that is required for a healthy yeast during its growth process (particularly free amino nitrogen – malted barley contains much of this in the beer brewing process). These nutrients are significant to yeast because they help strengthen yeast cell walls, prepare them for fermentation, and ensure essential reactions occur. The absence of certain vitamins, minerals and amino acids also contribute to slow, sluggish or stuck fermentations.

When there are nutritional deficiencies, the occurrence of off flavours and sulfuric aromas can also occur. The most extreme example of this is during Hard Seltzer fermentations where a sugar wash is fermented and the product remains clear and fairly neutral in flavour. The development of a nutrient blend with this fermentation in mind gave Murphy and Son the opportunity to think about each constituent individually and balance them perfectly for this particularly difficult environment for the brewing yeast.

Nutrient supplementation case study using Murphy and Son hard seltzer kit.

The Murphy and Son Just Add Sugar kit is a combination of nitrogen, vitamins, amino acids, yeast extract, and trace elements optimised to aid yeast growth during the fermentation of sugar solutions.

Just Add Sugar is formulated to provide the building blocks required for healthy yeast. The kit also comes with a buffer adapted to maintain a constant intracellular pH in yeast during sugar fermentation whilst decreasing the inhibitory effect of organic acids on yeast growth.

The salt magnesium sulphate (MagSul) forms the 3rd component of the kit. This provides the essential cofactor needed for glycolysis. The combination of each Murphy and Son Just Add Sugar kit component in the advised doses provide all the necessary elements for a successful sugar fermentation.

Following laboratory trials, Just Add Sugar formulation was prepared for a commercial production trial at a brewery. The initial sugar wash was carried out using granulated cane sugar (50 kg) and water (600 litres). The gravity of sugar wash was constantly monitored to ensure target OG was met (1.30-1.35). The sugar solution was boiled for ≈15 minutes and allowed to cool slightly before Just Add Sugar nutrients were added (an important step to avoid the denaturing of the product). The sugar solution was cooled further before transfer to the fermentation vessel (FV). Yeast was added following transfer of sugar wash to FV.

Hard seltzer production results

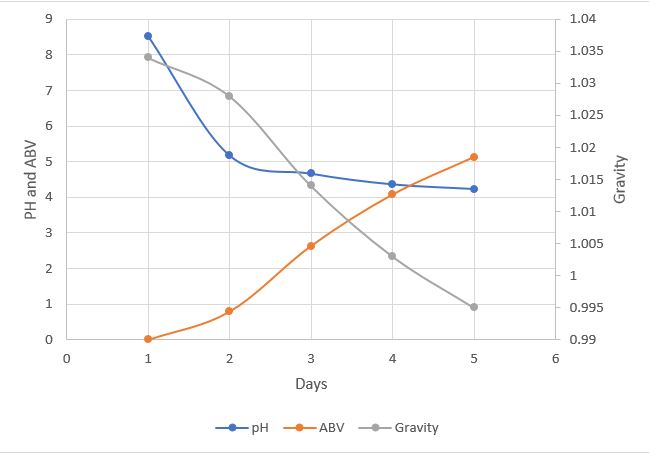

Graph above shows the pH, ABV and Gravity readings for the completed 5.12 % ABV hard seltzer. The fermentation attenuated with pH 4.23 and a final gravity of 0.995. The fermentation progressed well and created a base with the required properties. This pH allows for both an optimum range for yeast fermentation but also allows for the addition of acidic flavours further down the process without the final product getting too acidic.

The phases of yeast growth could be spotted on the graph with a lag phase in the first two days and a steady log phase between days 2 and 4. The stationary phase of yeast growth is preceded by attenuation in fermentation resulting in the clean alcoholic product at the target ABV.

Based on the result, it can be concluded that the nutrient had the perfect properties for fermenting a nutrient-poor media such as that used for the hard seltzer fermentation.

Murphy and Son Just Add Sugar nutrient can also successfully achieve a fermented sugar base for higher % ABV targets so that a more concentrated version can be made and liquored back later.

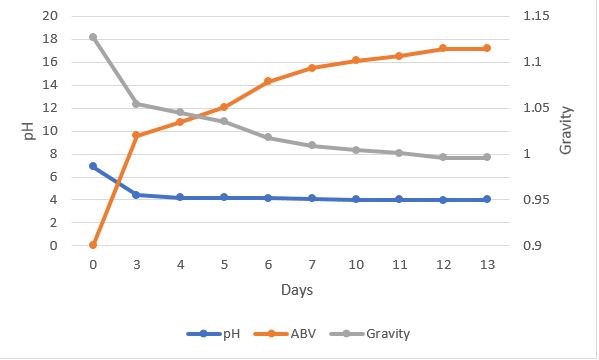

The graph above shows the pH, ABV and Gravity readings for the completed 17.2% ABV hard seltzer. The fermentation attenuated with pH 4.03 and a final gravity of 0.996.

This ability to successfully ferment high gravity sugar washes, especially at such fast rates, will also appeal to sugar-based spirits and other sugar-based alcoholic beverages.

Want to know more? Read the Just Add Sugar Sales Sheet here

Looking to add hard selzter to your portfolio? Find out more from our from our technical team at techsupport@murphyandson.co.uk