Guest blog- Words by Andy Paterson of Lallemand Brewing

Lager, everybody knows it. Over the past 150 years lager has risen from humble beginnings in the beer cellars of southern Germany, to become the words most popular style of beer; and while a diverse category in its own right, encompassing many different styles, colours and flavours, the particular type that has come to dominate the worlds beer landscape is a pale low strength beer, somewhere between a Pils and a Helles.

So everybody knows lager, but at the technical level,what is it?

The question is harder to answer than you might think. In German, the word lager means “to store”, and historically these beers would have been stored for long periods, whereas modern day maturation tends to be shorter. The beers of old were e typically fermented at cool temperatures, but again, while lower temperatures are often employed in the modern process, this is not always the case.

So what really makes a lager, a lager?

One of the more compelling arguments which could be used to define the style is the yeast used for fermentation.

While certainly not a watertight definition, yeasts used for lager production are very often genetically distinct from those used for ales. Ales are fermented using the yeast Saccharomyces cerevisiae, the same as is used for dough fermentation, and the primary species in the production of most wines and ciders. Conversely, lager employs a distinct species of yeast called Saccharomyces pastorianus.

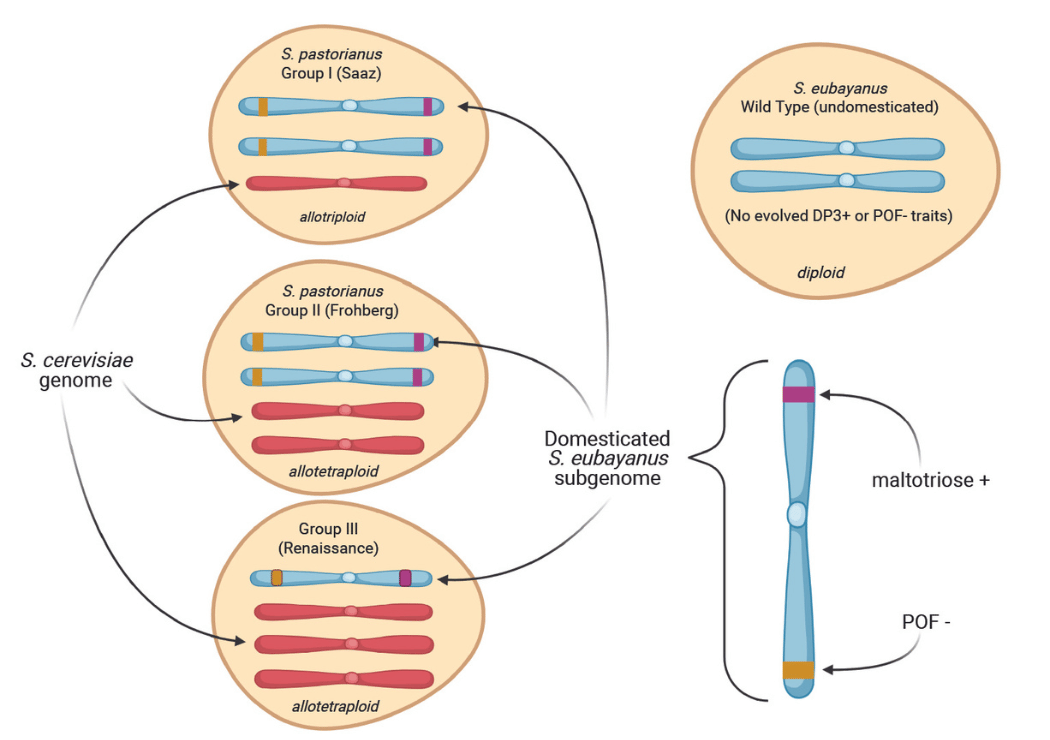

Saccharomyces pastorianus has an interesting history. Genetically the species has been found to be a hybrid created by a rare breeding event between the aforementioned Saccharomyces cerevisiae strain, and a recently discovered wild ancestor yeast, Saccharomyces eubayanus. Being a relative youngster compared with Saccharomyces cerevisiae, Saccharomyces pastorianus is less diverse within the species meaning differences between lager yeasts are less pronounced than their ale counterparts. The species comprises of two groups of yeasts Saaz, (Type 1) and Frohberg, (Type 2). In practice most yeasts used for lager fermentation are of the Type 2 type. Lalbrew Diamond is the Lallemand Type 2 lager yeast for example.

The lager yeasts derive some of their genome from the Eubayanus parent, which leads to the cryotolerance and distinct lager like flavour profile, the rest comes from Saccharomyces cerevisiae which allows for efficient fermentation of the wort sugars maltose and maltotriose, see figure 1 for chromosomal detail. However, despite a few hundred years of time to adapt to brewery environments, lager yeasts still retain some of the downsides of their wild ancestors as well. Fermentation times are still sluggish compared to ale yeasts, flavour profiles can be unacceptable at warmer temperatures, the strains are inefficient at reducing diacetyl and have a tendency to produce sulphurous off flavours.

So if new strain can be created naturally by a hybridisation, can we emulate this process in the laboratory to create new strains with desirable properties?

The answer is yes! Lallemand have been working with a Canadian company called Renaissance Bio Sciences, experts in the hybridisation of yeast for several years to bring novel hybrid yeasts to the market. The latest of these is our new Lalbrew Novalager yeast. Lalbrew Novalager is a hybrid lager yeast which is distinct from the current Type 1 and Type 2 yeasts. Lalbrew Novalager defines a new category of selectively bred lager yeasts, a Type 3 lager yeast, see figure 1.

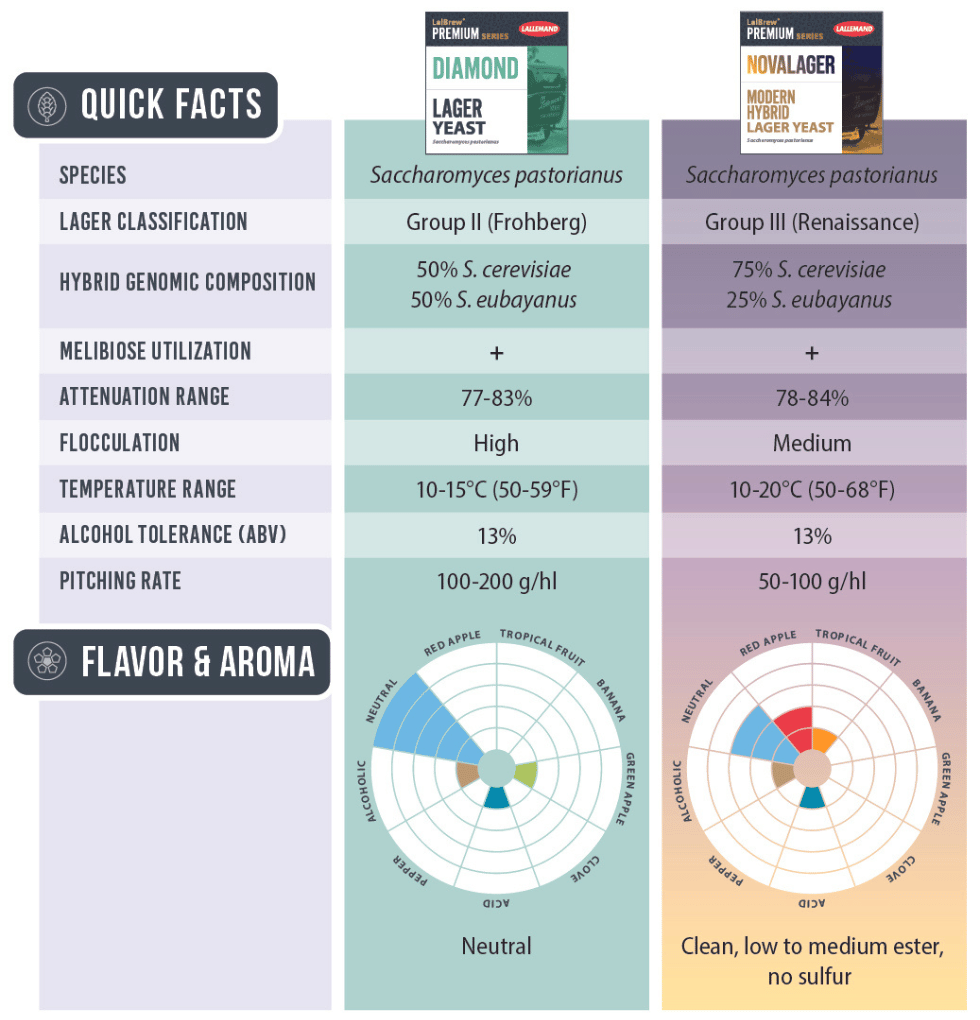

Compared with a Type 1 or 2 lager yeast, Lalbrew Novalager contains proportionally less genetic material derived from the wild Saccharomyces euybayanus parent, and proportionally more genetic material from Saccharomyces cerevisiae. The consequence of this shift in genetic ratios is that Lalbrew Novalager retains a distinctive lager flavour profile while attaining an ability to ferment at warmer temperatures, without creating off flavours. This allows for faster and more efficient fermentation.

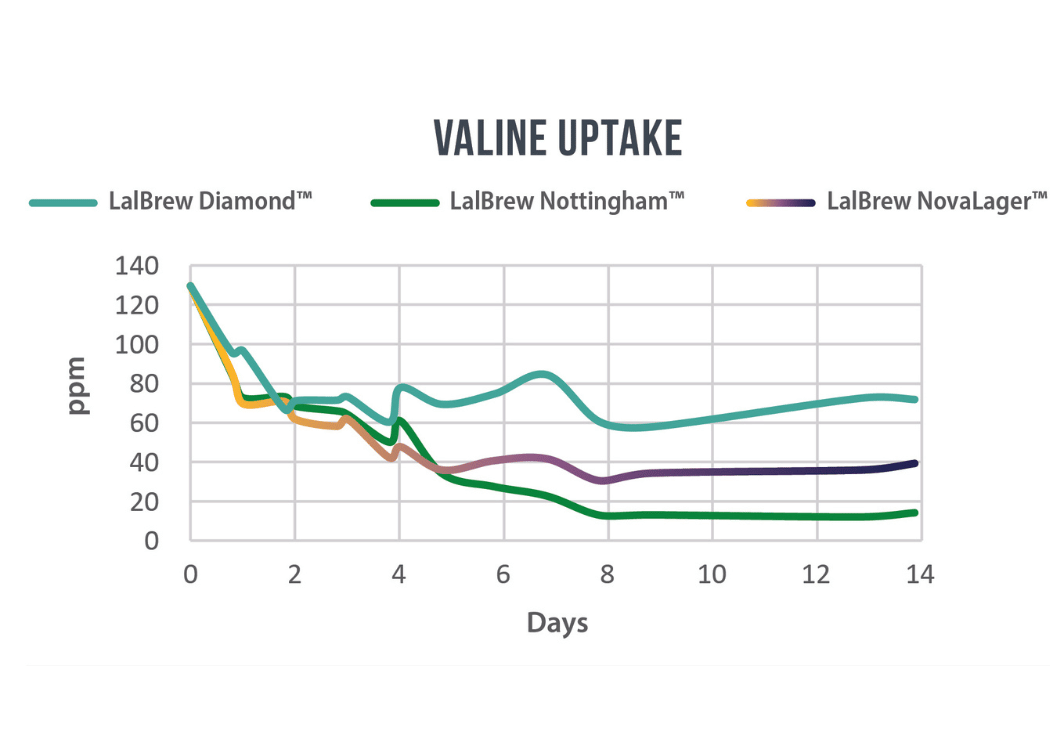

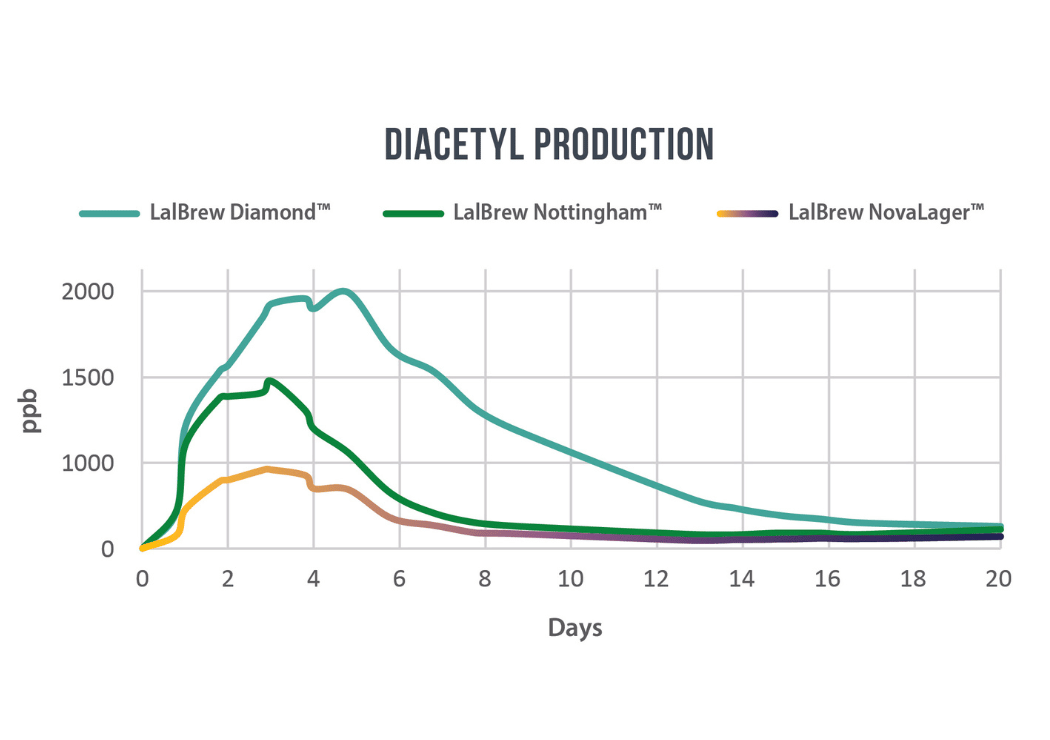

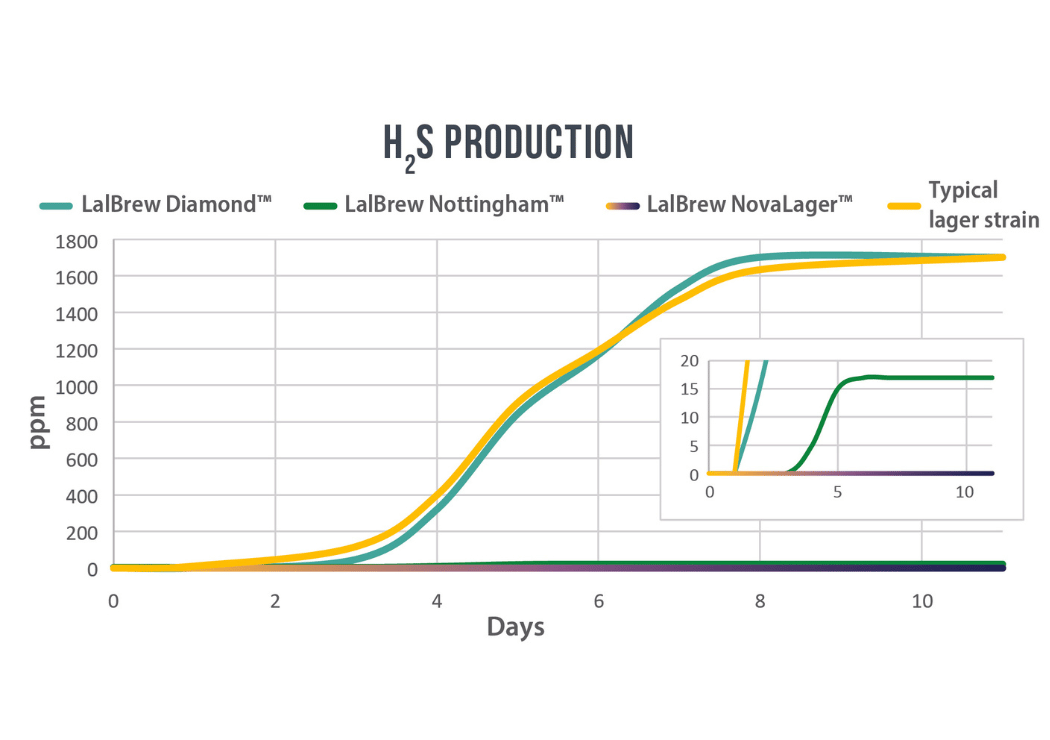

At the same time, the strain utilises the amino acid valine more like an ale strain, producing a lower peak in diacetyl during fermentation, see figure 2 and 3. The hybridisation process also incorporated a technology known as MET10, originally discovered by UC Davis in California, this technology incorporates a pathway within the yeast that prevents the strain from being able to produce the H₂S off-flavour, see figure 4. One final consequence of the hybridisation process is that the strain grows to a higher cell density in propagation processes, and therefore has a lower pitching rate than traditional lager strains. Novalager has a pitching rate of 50g/HL instead of the usual 100-200g/HL for a traditional strain.

To sum up, Lalbrew Novalager represents the next generation of lager yeast, able to ferment efficiently at warmer temperatures while retaining lager like flavour, and reducing the traditional long maturation times. The benefits of Lalbrew Novalager go beyond faster turnaround times and at a time of rising energy cost also mean that less energy is expended in cooling fermentations.

For a side by side comparison of Novalager and Diamond, the Lallemand type 2 lager yeast, see figure 5.

To find more about the the Lallemand premium range and to shop NEW Lallemand Yeast Novalager and classic Diamond Lager yeast, Click here