Our guest blogger this week is Jannik Munksgaard, a Danish brewer with a career spanning almost 40 years.

With DuPont, Jannik is the head of the Brewing Application Team

He is passionate about brewing, expanding the borders of how brewing is perceived, the endless possibilities of modern biotech, but first and foremost passionate about exceeding the customer expectations.

Let’s check in with him and find out more about the Enzyme Amylex 5T.

And the Brew Uniquely enzyme of the month is… AMYLEX® 5T !

Amy who?

AMYLEX® 5T, it’s an amylase enzyme.

Again, a what?

An amylase enzyme, without amylases there would be no beer.

No beer? That’s serious, you’d better tell me more…

The fact is, Alpha-amylase enzymes are truly essential in brewing. Alpha-amylase is one of the enzymes which occur naturally in malted barley. Brewers were taking advantage of its special properties for centuries before enzymes were ever discovered.

Without alpha-amylases it would not be possible to convert the starch from barley into the fermentable sugars necessary to produce beer.

However, the levels of endogenous alpha-amylases in malted barley can vary considerably due to climatic conditions and grain variety. Depending on the weather that year the perfect malt may be unavailable or very costly.

Additionally, individual brewers have differing ideas of their ideal beer; they may wish to brew more sustainably using unmalted barley, or perhaps using alternative locally sourced raw materials which may not naturally contain sufficient levels of alpha-amylases.

Using exogenous brewing enzymes such as AMYLEX®5T allows brewers the flexibility to adapt to these challenges and create their own unique brews.

How does it work?

Alpha-amylases helps to break down starch, cutting it into smaller pieces that can then be fermented. Starch is a complex carbohydrate consisting of long chains of glucose molecules. Cereal grains such as barley and wheat are important starch sources, and it also occurs in other grains, as well as in legumes, fruits and vegetables. Starch is made up of two components, amylose and amylopectin.

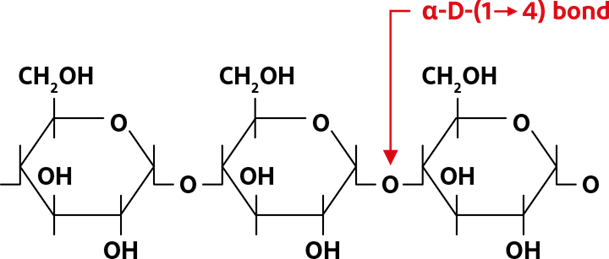

Amylose is a straight chain of glucose molecules conntected with α-D-(1->4) bonds – see figure 1. In nature amylose curls up into a helix.

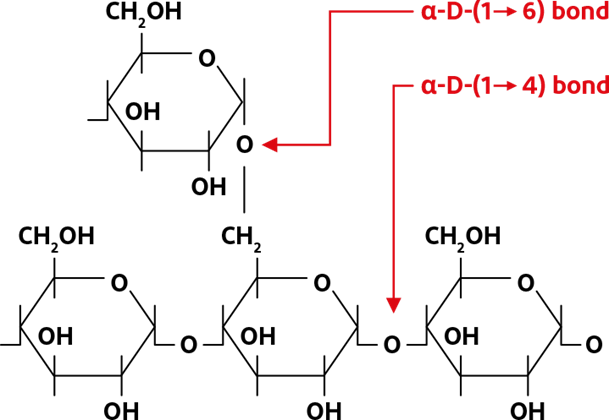

Amylopectin is made up of smaller or longer chains of amylose, which are connected with α-D-(1->6) bonds – see figure 2. This gives the amylopectin molecules a branched structure. Depending on the source of starch, the amylopectin molecules differ in the number and density of the branches.

The ratio between amylose and amylopectin also varies considerable between starch sources. In so-called waxy varieties of cereal, there is no amylose only amylopectin.

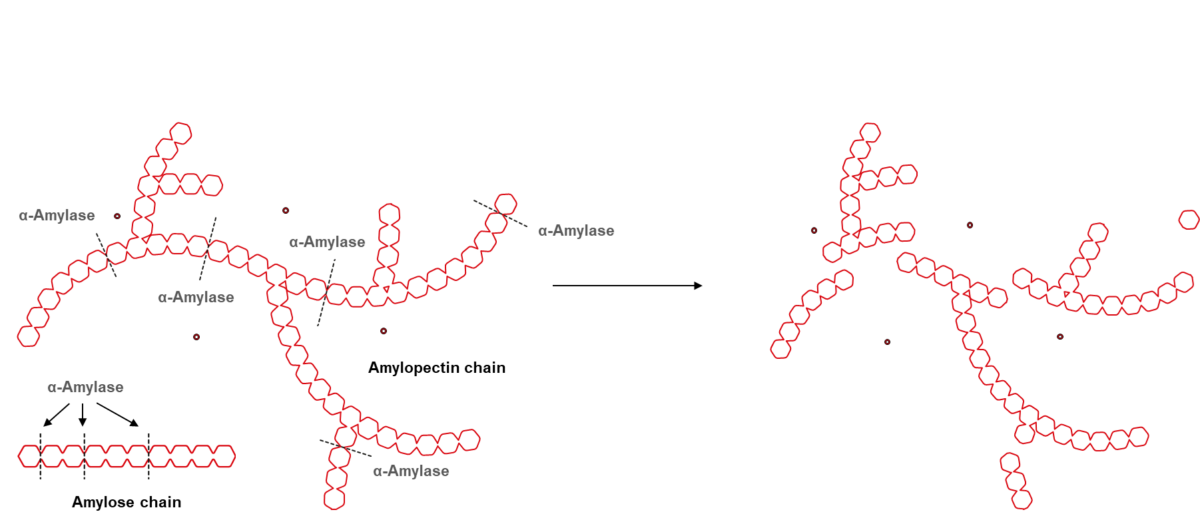

The initial, enzymatic break down of starch is also known as liquefaction. This is because if starch is heated in water without enzymes the solution will thicken, but the addition of alpha-amylase helps to cut the longer starch molecules into smaller pieces.

This makes the solution thinner turning it into a liquid again. This liquid contains the smaller fermentable sugars that remain after the starch is broken down – see figure 3.

Now fermentation can begin.

OK, I see alpha-amylases are useful. But why bother choosing a particular amylase? What’s so special about AMYLEX® 5T?

Well, not all alpha-amylases are equal. They differ in thermostability, pH tolerance, efficiency and last but not least in how they cut the starch.

Like all proteins, enzymes change structure when heated up to a certain temperature. This process is irreversible. After an enzyme changes structure it loses its ability catalyse the reaction it promoted at lower temperatures. The temperature at which an enzyme loses it’s structure and ability to catalyse is its level of thermostability.

Efficiency refers to how many reactions an enzyme molecule can support at one time. Most enzymes are more efficient at higher temperatures, promoting more cuts in the same time. This is the reason why thermostable enzymes are often preferred.

Now to cutting the starch. There are basically two different ways in which amylases cut starch. In one the reaction runs along the amylose chains from the outside of the molecule to the inside cutting randomly as it goes. The other reaction “just” randomly cuts the molecule. Just randomly cutting leads to a much faster reduction in the size of the starch molecule, which in turn leads to faster liquefaction or viscosity reduction.

Fast viscosity reduction is desirable for many reasons. These include a lower risk of burning heating surfaces in the mash vessel, and lower energy requirements for agitation in the vessel.

So how does AMYLEX5®5T compare with other amylases?

Well, we don’t want to brag, but… AMYLEX® 5T comes out on top of the list for all these aspects.

- It is very thermostable and can be used up to boiling point without any issues

- It functions effectively across a wide pH range

- It has a high propensity to cut starch molecules randomly, making it highly efficient for viscosity reduction

- It is very efficient, with a low dosage requirement and a very appealing cost-in-use.

Brew something different with AMYLEX®5T

AMYLEX® 5T is one of our best thermostable alpha-amylase for adjunct liquefaction. It is a flexible enzyme that works across a wide range of brewing recipes and processing conditions, reducing viscosity quickly and efficiently, whatever unique combination of raw materials you choose.

DuPont has many more specially engineered brewing enzymes providing individual solutions for creative brewers.

That sounds great, how do I choose the right enzyme for me?

We know that every brewery is different with a unique vision and set of circumstances. Which enzyme is right for you? AMYLEX®5T or one or more of our many other advanced brewing enzymes? Could it even be AMYLEX®6T? The rumour is it’s coming soon.

For more information on how to pick the right enzyme for you, please contact techsupport@murphyandson.co.uk or call us 0115 9785494.