After 15 years of working closely with craft brewers, it is becoming more and more evident that the most successful brewer is actually an obsessive cleaner that brews a bit on the side. The importance of cleaning in the brewing plant is paramount with its’ main purpose being the removal of soil from all surfaces of the plant leaving it in a suitable condition for use.

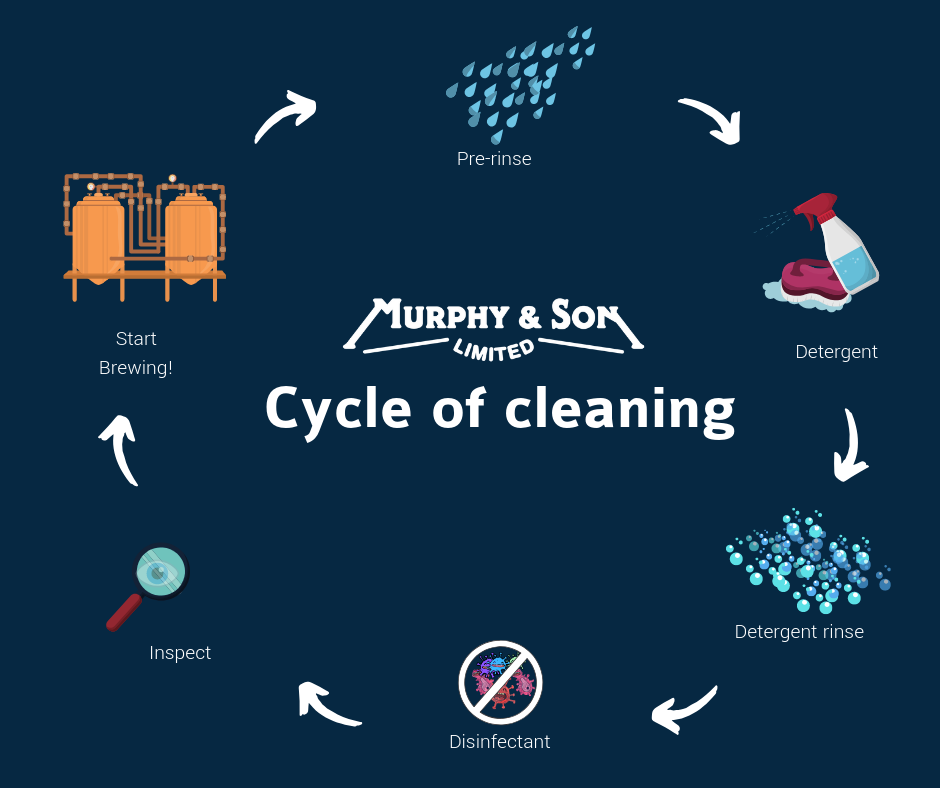

Once the brewing process is finished, the plant needs to be cleaned straightway to prevent any stubborn, ingrained residues forming during drying. The most effective routine for cleaning is to firstly carry out a pre-rinse, this process helps to remove loose material, this will eliminate 95% of the soil.

A detergent wash is then introduced by applying a diluted chemical in solution to the surfaces. This chemical and any dispersed residues need to be removed by rinsing with water. A sanitiser may be required after the rinse to ensure the surface is microbiologically clean and then the final stage is an inspection to check that the plant is ready to start the brewing process again.

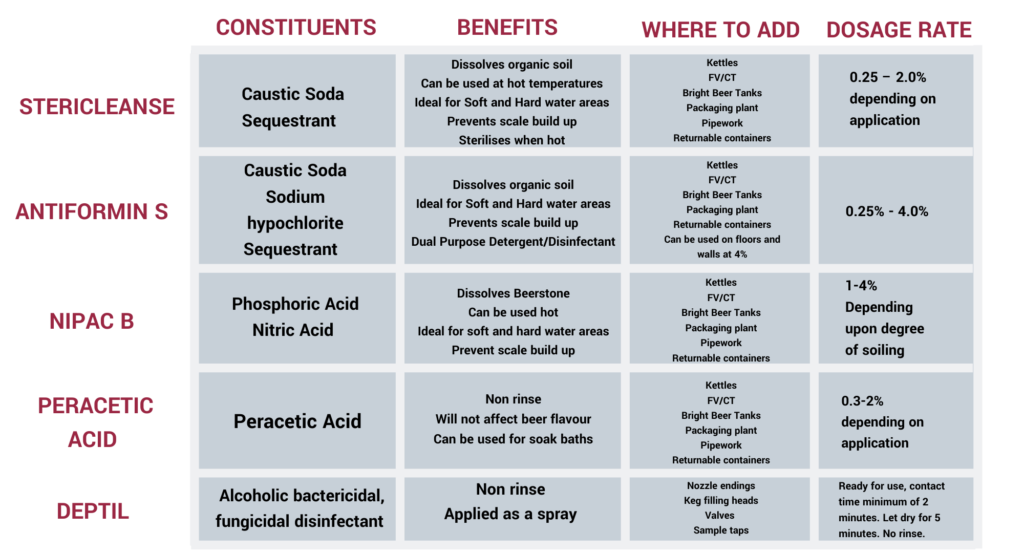

Choice of detergents

The choice of detergents to be used in the process will all depend upon the nature of the deposits found and water hardness. These deposits fall into two categories of soil types, organic soil deposits such as yeast, protein, fat, and sugar. The other soil type, inorganic soil, includes scale or beer stone. The main role of detergents is to penetrate the soil, dissolve it and then disperse the soil so it does not re-deposit back onto any surfaces and then eventually the soil is carried away during rinsing.

Most detergents contain wetting agents (surfactants), these are to reduce the surface tension of the water used in detergents to help increase the detergent’s wetting power. Without these wetting agents, water would sit on the surface like beads and would not achieve the desired coverage of the surface.

When dissolved by the detergent the soil will be removed from the plant surface and then can be carried away easily. Organic soil deposits are most efficiently removed by alkalis like caustic based cleaners. Whilst acids, remove inorganic soil deposits. The temperature that detergent works at plays a huge role in its performance. The action on caustic soda is more powerful at higher temperatures than at low temperatures.

The caustic soda based detergent Murphy’s Stericleanse contains a sequestrant. Any hygiene product that contains a sequestrant is perfect to use in hard water areas to prevent scale build-up.

Another detergent that Murphy’s can offer is our manufactured Antiformin S, this sequestered blend of sodium hypochlorite and caustic is ideal because of its low cost and its highly effective dual-purpose nature, as a detergent and sterilant, due to its presence of chlorine, however, temperatures of this product should not exceed 50°C.

To remove or dissolve existing inorganic scale, Nipac B is recommended which is a blend of nitric acid and phosphoric acid. For any soil deposits that are difficult to dissolve, detergents containing substances that help disperse the soils and hold it in suspension so it can be rinsed away are beneficial. To prevent soil re-settling onto the plant surfaces, the dispersed matter can be broken up using surfactants.

Areas, where detergents should be used regularly where high levels of organic soil will be present, are kettles in the brewhouse, fermenting vessels, yeast handling plant, maturation and conditioning vessels, bright beer tanks and all process pipework. Areas that also need full attention are packaging and bottle washing machines.

Stericleanse and Antiformin S are suitable for all these areas and can come into contact with stainless steel, copper and most plastics.

Nipac B is also ideal for these areas where there is a build of scale and can also come into contact with all of these mentioned surface materials. The cleaning cycle should always be completed with a thorough rinse. No soil or detergent should be left on any surface. Detergents have to be rinsed thoroughly.

Disinfecting/sterilizing

A successful cleaning regime in the brewery should always be followed by a good disinfecting/sterilising technique. This is to ensure all microorganisms on internal surfaces after cleaning are destroyed so that beer and wort are not contaminated.

Sterilants and disinfectants work by creating conditions that destroy microorganisms such as temperature, pH and surface activity.

There are several types of sterilising / disinfectant agents however most are not suitable for the brewing process as some are toxic, corrosive or could taint the beer. Hence here at Murphy’s, we have a specific range.

The Murphy & Son Cleaning range (Core 5)

Some breweries rely on heat from hot water or steam to achieve sterilisation and can be effective as long as the temperature is as high as 90 °C for at least 15 minutes. A chemical disinfectant that is suitable for the brewing process from the Murphy & Son range is, as discussed earlier, Antiformin S, although its primary purpose is a detergent due to the caustic soda content it also contains chlorine which can be used as a fantastic biocide.

Please be aware that Antiformin S can lose its effectiveness in the presence of organic matter or at high temperatures, therefore the correct dosage rate of the product should be used at temperatures no higher than 50°C. This product can leave a taint if not rinsed off thoroughly.

Stericleanse can also be used as a disinfectant at really high temperatures of 90 °C for at least 15 minutes, this product must be rinsed off. In this case, it is the temperature that acts as the sterilant.

After the final rinsing stage, a terminal sterilant can be applied, for example, Murphy’s Peracetic Acid which breaks down to water and oxygen so it can be left without rinsing. We highly recommend to use this product at the final stage of any cleaning regime, it is highly effective, safe at working strength and will not affect beer flavour.

Peracetic acid is also ideal for soaking small items overnight or beer mains and hoses may be filled after cleaning. Peracetic acid under these circumstances must be drained off. Large vessels and plants can be treated using a spray ball or a fog gun.

For areas more prone to contamination such as nozzle endings, keg filling heads, valves, and sample taps to ensure that their surfaces are microbiologically clean an alcoholic, bactericidal, fungicidal and disinfectant spray can be used such as Deptil.

In preparation for the brewing process to start over again, an inspection and approval procedure should be in place. This can be done by checking visually, it’s quite common for a brewer to invest in an inspection torch, by smell or touch (check if it squeaks).

Another method is to use a bioluminescence device, Murphy’s can supply a hygiene system sure II which monitors the presence of ATP, this is the energy molecule found in all living and once-living things, making it a perfect indicator for cleanliness.