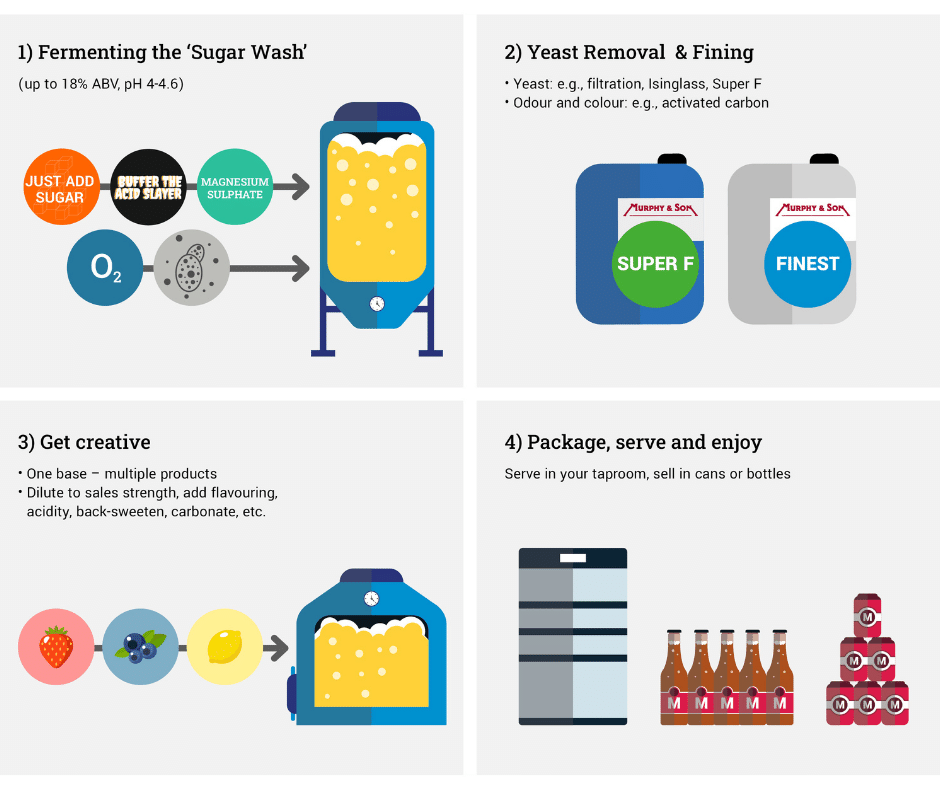

We all enjoy brewing, and we all love our beers! But have you ever considered that with a few simple steps, you could extend your beverage portfolio and start selling sparkling alternatives and your very own cocktail creations to both beer and non-beer lovers? Creating your very first hard seltzer or Ready To Drink (RTD) cocktail in your brewery is easy – if you know how!

In the following blog, we are going to show you how to

- Make your very first (fermented) neutral alcoholic base

- Create different cocktail recipes

- Ferment your first Hard Seltzer directly to sales strength.

Exciting times for us brewers. No new equipment necessary, one alcoholic base, multiple recipes – for every taste. Let’s get ready – Summer is coming!

1 Let’s get it started

The ingredients in a typical fermented neutral alcohol base are simple – water, sugar and of course yeast and yeast nutrients. However, the process is sometimes plagued with long or stalled fermentations, as well as significant off-flavours in the final product.

This is primarily due to i) the absence of succinct nutrients in the sugar solution required for a healthy fermentation, ii) wrong choice of yeast strain, or iii) insufficient aeration for high gravity ferments. Yeast nutrition is an essential factor in the overall health and success of fermentation. ‘Just sugar’ is not enough to keep the yeast happy, it requires sufficient amounts of YAN (yeast assimilable nitrogen), vitamins and minerals! Murphy’s ‘Just Add Sugar’ is a blend of nutrients, specifically designed to make your very first clean, dry and clear neutral alcohol base or ready-to-drink hard seltzer. Additionally, simple sugar-based fermentations have zero buffering capacity, in contrast to beer, cider or wine fermentations.

To avoid a rapid drop in pH and maintain an optimal pH for yeast health, we formulated the JAS-Buffer, which will keep your pH above 4.0. For low and high gravity fermentations- simply adjust your addition rates. Naturally, there are different strategies for making hard seltzer or fermented alcoholic bases, depending on the priorities and target of the brewer.

Here are a few suggestions to get your new adventure started:

- Struggling with availability of fermentors? One possibility to creating several drinks from just one ferment is by making a high-gravity sugar wash and diluting to sales strength after fermentation.

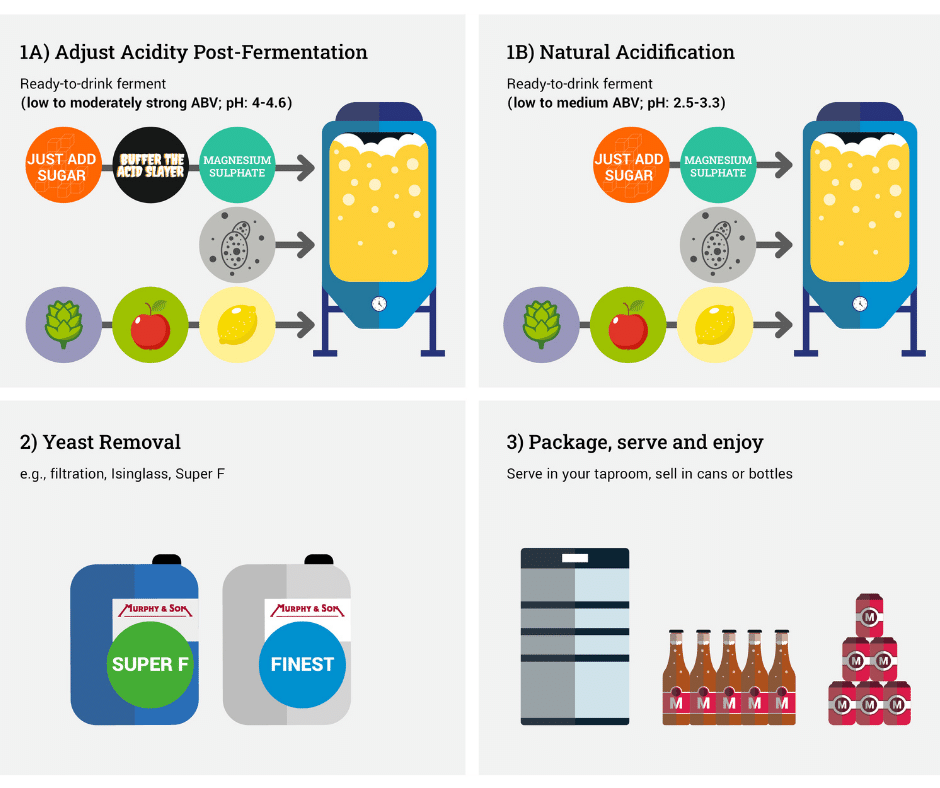

- Would you prefer fermenting directly to sales strength? Simply pick your flavours and add them directly into the fermentor! Better yet, the sugars sourced from these flavourings will be fermented and leave you with a clean, dry product. You can simply adjust the pH of your ferment after fermentation with malic or citric acid, to add some ‘zing’ (Figure 2; 1A) and even back-sweeten to taste. If you decide to back-sweeten your product, don’t forget to stabilise your product, using e.g. potassium sorbate. Alternatively, as these sugar-based fermentations lack buffering-capacity, you can take advantage of the natural acidification by not adding the buffer (Figure 2; 1B). But be careful, as pH decreases yeast will increasingly struggle to ferment to high strengths.

2 High strength neutral base – Practical examples and recipes

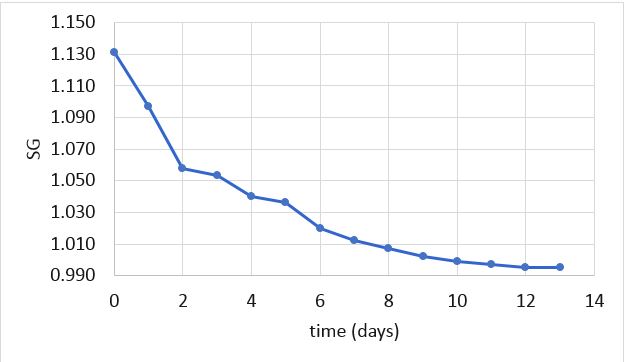

Example 1: 17.8 % ABV neutral alcohol base

| Finished product specifications | Equipment | Ingredients |

| 17.8 % ABV neutral base pH: 4.2 SG: 0.995 Colour (ABS 430): 0.019 | Grainfather G30 Conical fermentor Glycol chiller Aerator 0.2 μm syringe filter | Table sugar (~341 g/L) Tap water Just Add Sugar Yeast Vit (3.5 g/L) Just Add Sugar MagSul (0.22 g/L) Just Add Sugar Buffer (2.64 g/L) Yeast Lalvin EC1118 (1.1 g/L) |

Brewing day

- Please sanitise all equipment prior to starting your brewday!

- Add table sugar to water (30-40◦C) and mix until fully dissolved. Adjust gravity if necessary to ~1.129 and boil sugar wash for 10 minutes.

- Cool down to 30◦C with the help of the counterflow chiller and transfer directly to the sterile conical fermentor.

- Add all Just Add Sugar components (Vit+MagSul+Buffer) and aerate sugar wash through the rubber stopper for 30 minutes using a (fish tank) aerator and airstone (Figure, left). To remain sterile, attach a 0.2 μm syringe filter to the tubing.

- Turn off the aerator and sprinkle yeast on top of the sugar wash. Seal the fermentor.

- Wait for 1 hour prior to turning the aerator back on.

Ferment at 24◦C and stop aeration when your fermentation reaches log phase (when the fermentation kicks off). Insufficient aeration for (very) high gravity sugar washes will end up in a stalled fermentation. After aeration is finished, insert the airlock back into the rubber stopper (Figure 3, right).

- Once fermentation is finished, chill your fermentor and add finings (Isinglass or Super F) to remove yeast from bottom of the fermentor. In contrast to beer, simple sugar-based fermentations do not contain any buffering capacities. Our JAS buffer helps to maintain the pH above 4.0, to avoid fermentation issues, and enables finings (Isinglass, Super F) additions at the end of fermentation.

Your 17.8% ABV base is ready to be blended!

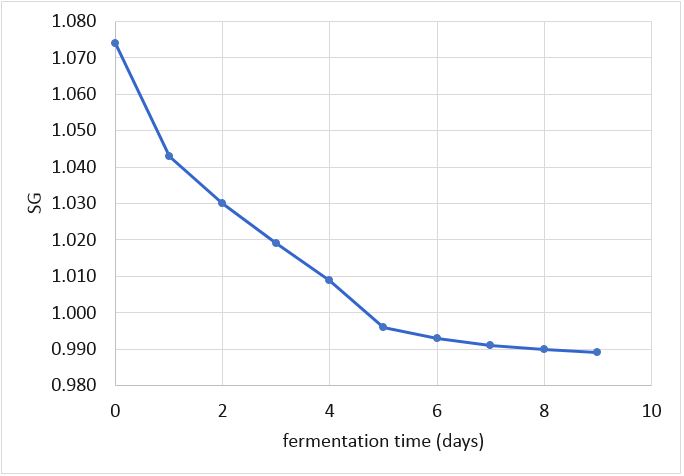

Example 2: 11.3% ABV neutral alcohol base

| Finished product specifications | Equipment | Ingredients |

| 11.3 % ABV neutral base pH: 4.4 SG: 0.989 Colour (ABS 430): 0.015 | Grainfather G30 Conical fermentor Glycol chiller Aerator 0.2 μm syringe filter | Table sugar (~182.5 g/L) Tap water Just Add Sugar Yeast Vit (2.2 g/L) Just Add Sugar MagSul (0.18 g/L) Just Add Sugar Buffer (2.2 g/L) Yeast Lalvin EC118 (1.1 g/L) |

Brewing day

- Pleasesanitise all equipment prior to starting your brewday!

- Add table sugar to water (30-40◦C) and mix until fully dissolved. Adjust gravity if necessary to 1.070 and boil sugar wash for 10 minutes.

- Cool down to 30◦C with the help of the counterflow chiller and transfer directly to the sterile conical fermentor.

- Add all Just Add Sugar components (Vit+MagSul+Buffer) and aerate sugar wash for ~10 minutes through the rubber stopper for 30 minutes using a (fish tank) aerator and airstone (Figure , left). To remain sterile, attach a 0.2 μm syringe filter to the tubing.

- Turn off the aerator and insert the airlock back into the rubber stopper (Figure 1, right).

- Sprinkle yeast on top of the sugar wash. Seal the fermentor and ferment at 24◦C.

- Once fermentation is finished, chill your fermentor and add finings (Isinglass or Super F) to remove yeast from the bottom of the fermentor.

Your 11.3% ABV base is ready to be blended!

3 Optional – Removal of off-flavours

Even with best practice techniques, you will end up with some colour (~Abs 430 = 0.012-0.02) and flavour, that’s mostly described as wine or cider-like. For some recipes, it won’t be necessary to remove them, as the addition of your flavours of choice will simply ‘cover’ them. Nevertheless, it is quite simple to remove them, as these odours are very volatile and easily removed. Here are some tips, that can be performed even on small scale:

- Activated carbon: Carbon treatment is an excellent technique for colour and flavour reduction of a neutral alcohol base.

- Odour removal with CO2. Carbon dioxide bubbling can help to remove unwanted volatiles in your beer. Don’t forget to vent the keg when purging with CO2, to allow these volatiles to escape.

Want help with your summer hard seltzers? Email techsupport@murphyandson.co.uk for support and recipe suggestions. Here is one to get your started;

Try our Strawberry and Passionfruit Cocktail recipe here

Try our Herbal Infusion recipe here

Try our Sparkling Passionfruit recipe here

Try our Classy one Recipe here