A recent survey suggested that 8.5 million people in the UK are following a gluten free or reduced gluten diet. This ever-growing market is proving increasingly tempting for brewers and with a few simple tweaks to the processing, brewers can achieve beers with less than the required 20 ppm of gluten with little or no noticeable difference in appearance and flavour.

Here are our top tips for successful gluten free brewing.

- Grist adjustment

- Processing

- Use of Brewers Clarex

- Avoidance of cross contamination

- Get the testing regime right

Grist Adjustment

It sounds like a simple statement but it’s a common-sense approach to manage how much gluten you put into the beer in the first place. Gluten is a composite of storage proteins found in the endosperm of grains alongside starches. Some types of grain contain more gluten than others. Wheat contains by far the most gluten followed by barley and rye.

Grist adjustment makes sense, with wheat reduction in mind, it will help greatly reduce gluten content.The addition of cereal adjuncts like maize, rice, sorghum and millet will also help to bulk up the gravity without adding gluten.

Take into consideration the use of brewing sugars, such as invert and syrups, to help increase the gravity of the brew all while adding zero gluten.

It is also worth noting that gluten is a protein complex. The nitrogen content of malted barley will also have a relation to the gluten content. It is always useful to talk to your maltster to see options for nitrogen content from season to season to help keep this aspect of your malt as consistent as possible.

Processing (Especially Copper Finings)

Protein management is a huge aspect of the brewing process and effective management of processing can help reduce gluten content in the final beer.

As always with brewing, this starts with the brewing liquor. Ensuring your mash pH and temperature hit your spec is also important. The effect of any potential changes in the malt quality can also be minimised with the addition of enzymes such as Trizyme to the mash. A good rolling boil with wort well fined with carrageenan will also start to reduce the level of protein present in the wort and in turn reduce the gluten content.

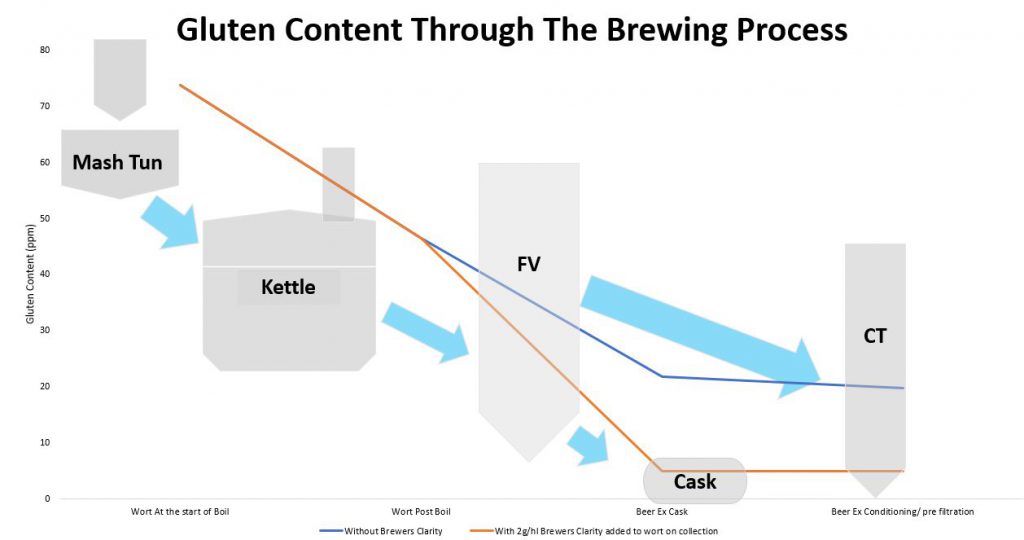

In partnership with Brampton Brewery, a recent Murphy and Son Survey (fig 1) established that a correct boil with optimised copper finings dropped will drop gluten content of the beer by as much as 30%.

Post fermentation, an extended conditioning time at low temperatures will also help to reduce the protein and gluten content by encouraging the protein to drop out with polyphenol complexes.

This process can be speeded up with addition of Finings and Silica Gels.

(Fig 1)

Use of Brewers Clarity/Clarex

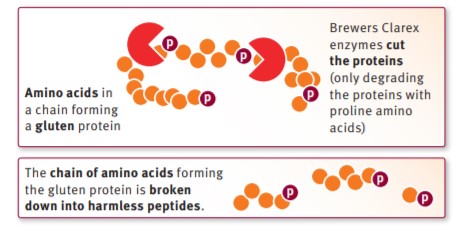

In addition, Fig 1 demonstrates the huge benefits of use of Brewers Clarex with the reduction of gluten in beer. Brewers Clarex is a Proline Specific Endo-Protease which offers a great solution to brewers for both gluten removal and prevention of the formation of protein-polyphenol complexes. These are normally attributed as the major causes of chill and permanent haze. 8 out of 10 of the largest global brewers now regularly use Clarex and its use is growing exponentially throughout the brewing sector.

Brewers Clarex is growing in popularity as it is very easy to dose: typically, 1-5g per hl added directly to the wort on collection in the fermenting vessel.

Addition at this point is beneficial as it mixes well and during a normal vigorous fermentation, yeast will naturally consume some of the smaller peptides preventing potential stability issues down the line.

Avoidance of cross contamination

If you are not an exclusive, gluten free brewer, contemplate the effects of cross contamination across the plant. Putting a procedure into place to make sure there is no cross contamination of raw materials is vital.

You should consider elements such as gluten carry over from skimmed / cropped yeast and contamination across filtration runs. Trying to make your gluten free beer the first beer processed following a deep clean will also help eliminate pick-ups across the process.

It is also worth considering these issues if you are using third party packaging companies.

All documentation such as HACCP’s, standard procedures and training records should be up to date to include any new steps in the process, especially as beer (in the main) starts off with gluten containing ingredients.

Get the testing regime right

Managing the testing regime when producing gluten free beer is a very difficult task.

The recommended starting point for any brewer is to try and produce a beer like the gluten free product and test to ensure that the beer is below 20 ppm before embarking on product launch.

This may seem a costly process however it will help iron out any issues and reduce their risk before launching a new product.

The current recognised test for gluten in the beer is the ELISA (Enzyme Linked Immunosorbant Assays) R5 competitive test. This test uses antibodies to test for gluten in beer.

This test must be conducted by an accredited laboratory.

In this test, samples are prepared in triplicate by degassing and centrification. They are then incubated at exactly 22oC for 30 minutes along with several laboratory standard samples.

A wash solution is then added to each of the samples followed by a substrate pink chromagon.

Following a second incubation period, a “stop solution” is added and the sample has light of wavelength 450 nm passed through it. The absorption of this light can then be measured with the gluten content inversely proportional to the absorption of this light. The data from all the triplicate samples and the standards are then used to plot a graph to determine the ppm of gluten.

Best practice is to get every batch of beer test for gluten content as late as possible in the process.

Many brewers test in tank before packaging but some retailers are now insisting extra tests are also carried out on the final packaged product. This is a difficult and time-consuming process but necessary due to the potential risk to public health.

We have a dedicated Lab , Technical Team and Gluten Testing Regime available at Murphy and Son to help you get free-from ready. If you would like to find out more information on pricing, sending in a sample and technical support available please click here.

Gluten Free Brewing can be a difficult extra process to handle but with careful management in the brewery and a few relatively minor tweaks, it is possible to produce great tasting beers with no noticeable changes in character.

With an increasing number of people moving away from food and drink containing gluten, when done well, this can be a great success for any brewer and provide a greater range of beer for people following such a diet to enjoy!

Read More Blogs