Brewers and beer lovers alike love the fantastic array of flavours and aromas that can be accomplished through dry hopping. An aroma compound not so commonly appreciated by brewers and beer lovers are Vicinal Diketones (VDKs). VDKs include Butane2,3-Dione (Diacetyl) and Pentane2,3-dione which are commonly described as buttery, butterscotch cream & toffee notes. It’s pleasant with popcorn and other tasty snacks but not so popular with beer.

Often described as an off-flavour, especially for pale lagers and hoppy ales, for some beers a level of Diacetyl is acceptable or even desirable. There are breweries with a minimum limit built into their specifications! Whether a house flavour or an off flavour, most brewers are looking to control this flavour active aroma to fit the profile of the beer brewed. Not an easy task especially with a flavour threshold that can be under 100 ppb.

Variations on a commonly used simple test for VDKs are described below;

- Take 2 x 100 ml samples of beer from maturation.

- Cover both with foil or Petri-film.

- Leave one sample at room temperature.

- Heat the other sample to 65 ͦ C and hold for 20 minutes.

- Cool the sample back to 20 ͦ C.

Smell and taste both samples the heating converts the precursors into the aromatic VDKs.

Continue maturation if levels are unacceptable in one or both.

When aromas are acceptable in both samples it is generally deemed ready for further processing.

Although a useful test to help monitor Diacetyl rests and maturation requirements, it is very dependent on the sensory skills of the individual or team. Even when training is completed, sensitivities can vary dramatically between individuals and can be influenced by external factors such as colds, food and drink consumption, smoking and even the time of day. The most accurate test is performed by GC analysis and is therefore only available to breweries with the most sophisticated lab facilities.

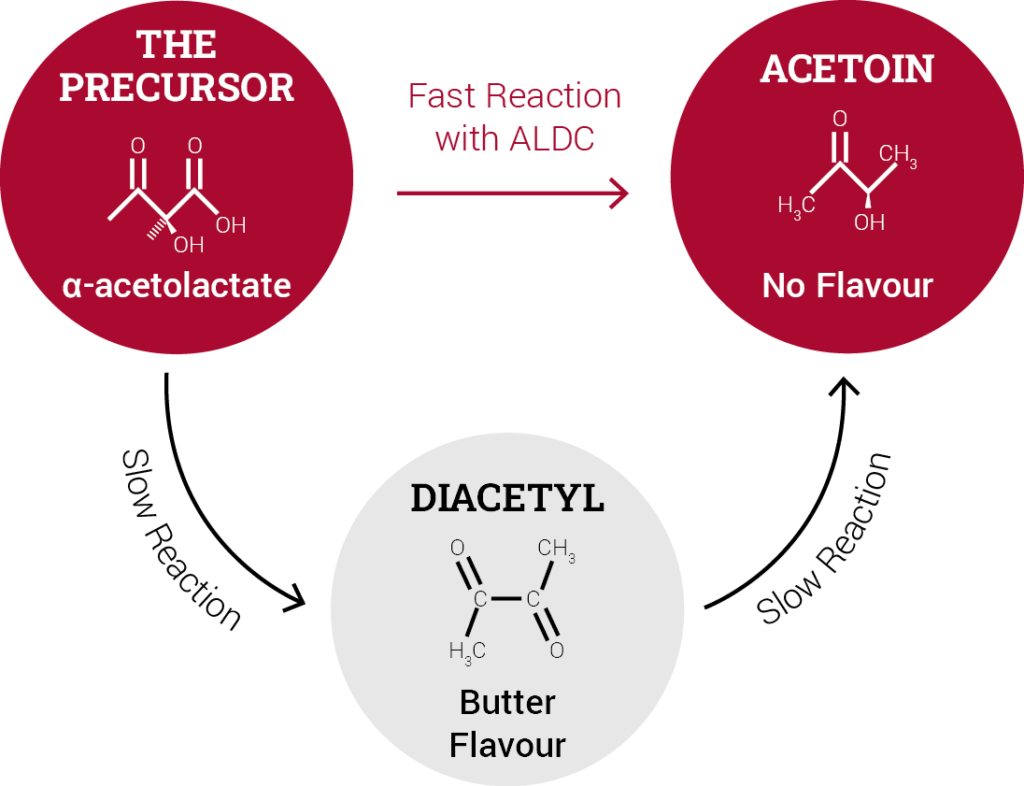

Many brewers, especially in the US, are utilising the alpha-acetolactate-decarboxylase enzyme as a simple convenient control measure.

Prevention is better than cure- ALDC bypasses the formation pathway

- Reduces Diacetyl production.

- Shortens maturation requirements.

- Ensures efficient production of beer.

- Ensures flavour standards are met.

“Hop Creep”

- Hops exhibit low levels of enzymatic activity.

- Dry hopping can produce more fermentable sugars over time.

- The renewed availability of fermentable sugars can result in further yeast activity and VDK production.

Use of ALDC can prevent VDKs reoccurring as a problem in dry hopped beers.

VDK’s can also occur as a result of microbial contamination so the use of ALDC is no substitute for strict hygiene controls.

The enzymatic activity of hops makes attenuation control even more critical especially when secondary fermentation is employed. The below attenuation limit test can be very useful although the slow enzymatic action of the enzymes from the hops can still cause problems with over carbonation in the package.

Attenuation limit test

This test can be employed to wort taken before fermentation.

- Fill a 750 ml sanitised flask with wort.

- “Overpitch” with a heaped teaspoon of the brewing yeast culture used.

- Add a cotton stopper and shake vigorously.

- Store at room temperature (~20 ͦC) and allow to ferment, measuring the gravity every 24 hours. Keep shaking intermittently or use a stirrer.

- When the gravity results stabilise for 48 hours the attenuation limit has been reached.

- The results can be used to modify the mashing regime to make the wort fermentable.

For those about to hop… we can help you!

Contact techsupport@murphyandson.co.uk or call us on 0115 978 5494 for further support.