With Alkalinity covered in Guide 1 it is time to get creative and start tailoring the additions to best express the flavours in your beer!

Water is the primary raw material in beer and much like laying good foundations is essential for building a good house, creating a suitable water (liquor) profile is essential for building a great beer.

Brewers have realised this for a long time and therefore it stops becoming water and becomes liquor when it is adjusted for brewing.

Tailored Liquor Profile Fundamentals

- pH of the brew is critical to quality. Alkalinity & Calcium levels set by creating a water treatment play the biggest role in controlling pH of wort and beer#. PH has a direct impact on flavour and processing.

- Sulphate (dry bitter): Chloride (Sweet, Malty & Fullness) concentration & ratio influences flavour

- Calcium not only influences pH but also Extract, Enzyme action, Protein Coagulation, Yeast Flocculation, Beer Stone prevention (& resulting gushing) & lowers colour formation.

#Malt type, Mill settings, Adjuncts, Yeast strain and other factors all play a part in pH control but are beer recipe or equipment fixed variables

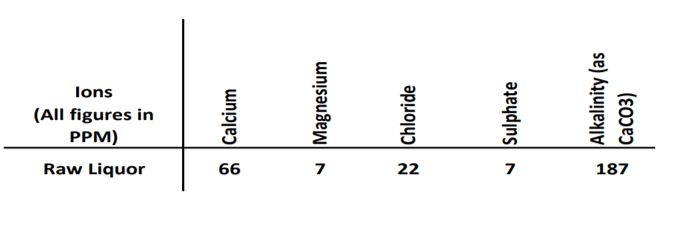

Your Water Source & how to improve it

- Regular Alkalinity checks in the brewery pre and post treatment {Guide 1}

- Intermediate full composition analysis Full analysis contact our {technical team} or your local distributer

- Chlorine removal- Metabisulphites (e.g. Metabs ), UV degradation or activated carbon

- Alkalinity control with AMS {Guide 1}

- Tasting throughout the brewing process including water treatment stages

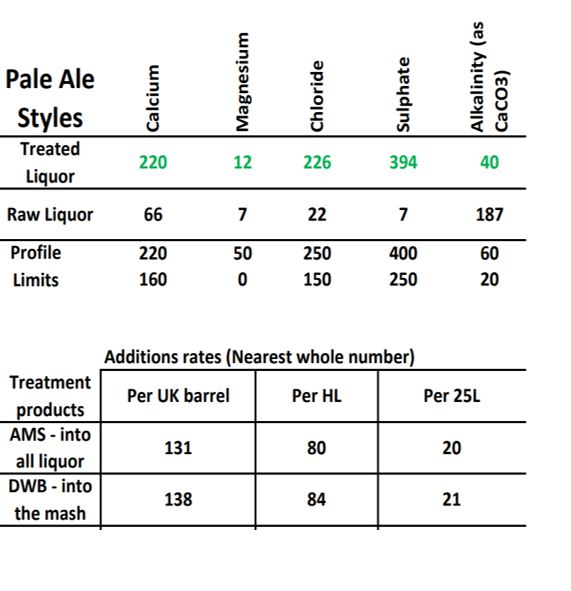

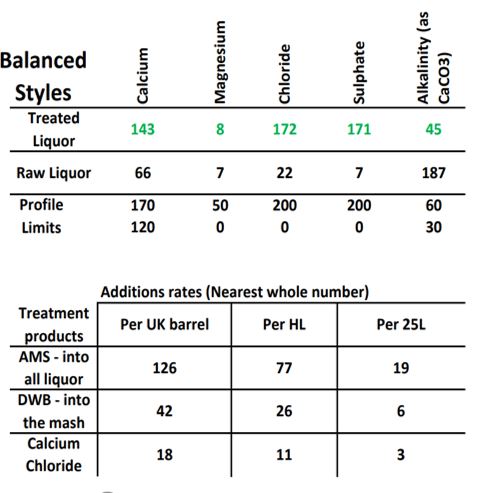

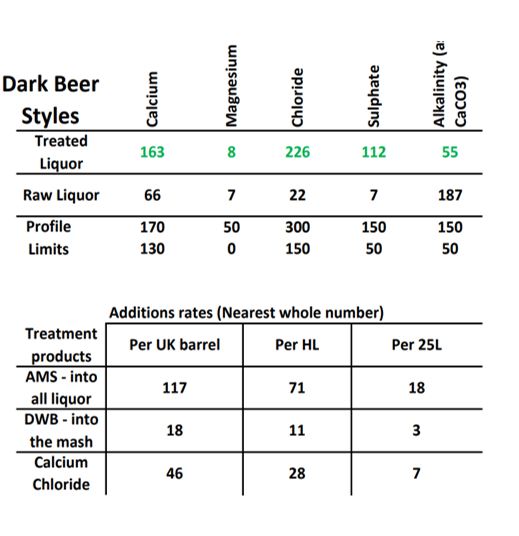

- Tailoring the water profile for each beer brand with brewing salts such as DWB Calcium Chloride (Flake), Calcium Sulphate (Gypsum)

Example Profiles & Trial Tips

When we receive a water sample, we analyse the raw liquor composition and provide simple recommendations based on a wide style grouping. This can be used as a broad starting point to tailor the profile for the beer recipe, additions will vary depending on:

- The grist composition e.g. Roasted malts have higher natural acidity

- Yeast strain(s)

- Brewing method & Philosophy e.g. Decoction vs Infusion Decoction results in a lower pH (~0.1 to 0.15 pH)

- pH target of the final beer and throughout the process e.g. Final Beer target 4.1 (+/- 0.1)

- What are the target flavours to enhance or influence with the liquor profile

- Packaging format and shelf life

Advice for interpreting results and benefits

Water profiles will impact many aspects of beer quality. When assessing benefits keeping detailed, accurate records will be crucial. Even with good record keeping it can be difficult to quantify all benefits.

Brewing good beer is a balancing act as changes often have benefits in one area only to be offset by a drawback elsewhere so it is important to prioritise the goals for your water profile.

- pH Meter– Having a quality, well maintained and calibrated pH meter is essential for measuring the liquor profiles impacts on pH in the brewery.

- Brewing equipment– Treating alkalinity and using correct water profiles will help keep your equipment shiny and scale free with less frequent acid cleaning.

- Appearance, Foam & Flavour– A good tasting team will be crucial to water profile development. Large changes in profile can be easy to appreciate e.g. Treatment Vs no Treatment but more difficult when it comes to fine tuning. Thankfully a brewing team will understand their beers better than anyone else and with regular sensory sessions, tasting beer & recording results at various stages of shelf life it is possible to make incremental improvements that transform a beer over time.

- Extract Yield & Saccharification time- Optimising pH through alkalinity control and calcium salt additions may only achieve marginal improvements in extract but saccharification time can be significantly reduced.

- Wort separation- the combination of alkalinity control and sufficient calcium will also improve wort separation to improved mash bed permeability. This is thought to be due to a reduction in fine particles in the grain bed. Improved coagulation should also lead to better hot break separation and removal.

- Fermentation- correct liquor profiles will improve free amino nitrogen levels (FAN). Calcium plays an important role in yeast flocculation and as a modulator for growth and metabolism.

- Stability pH is an important microbiological hurdle, correct liquor profiles benefit foam and reduce the risk of gushing in pack due to beer stone (calcium oxalate)

You don’t have to put your water source on display, but beer is mostly water– Treat it right!

For more information on how to tailor your water profile to suit your brewery, email our technical team at techsupport@murphyandson.co.uk