General Considerations

- The rate of fermentation depends on the pitching rate, the temperature at pitching (pitching heat) and the attemperation used during fermentation.

- The level of dissolved oxygen, amino acids, the carbohydrate spectrum and the temperature rise affect the degree of attenuation

- Excessive temperature can lead to off-flavour (ie. yeast-bite) and attemperation must be controlled without slowing the fermentation or causing yeast sedimentation. Shock cooling must be avoided during the active phase of fermentation.

- Rousing will assist in maintaining the yeast in suspension and increasing the level of dissolved oxygen and rate of attenuation.

- Fermentation systems and skimming regimes will affect attenuation, yeast crop, yeast count at rack and beer flavour

- Murphys supply a range of yeast foods, in liquid, powder and tablets which can be used to provide a supplement of trace nutrients for yeast growth. This should be regarded as an insurance measure and not as an essential requirement. However problems with poor malt quality (low FAN) or poor yeast vitality and viability can be helped by use of a yeast food.

Range of Values

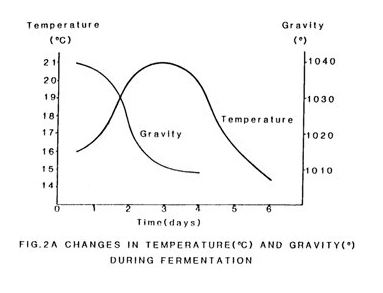

- Figure 2 at the bottom of this article shows typical changes in temperature and gravity during fermentation.

- Attenuation target should be between 1° and 3° above the attenuation limit. In general the racking gravity will not be more than a quarter of the original gravity

- For the range of values for dissolved oxygen, refer here.

- For Free amino nitrogen recommended levels, refer here.

- The range of maximum fermentation temperature should be 20° – 22° C (68° – 72° F).

- At skimming the gravity will not normally be more than 2° above the attenuation limit.

Operational Protocols

For best recovery of barm ale (and therefore yeast for further brews and also to achieve a consistent yeast count at rack) the ideal wort depth is between 1·8 and 3·0 metres (6 and 10 feet). Yeast food is added to wort prior to pitching.

There are 3 methods of rousing:

- Bottom Rousing for yeast dispersal.

- Top Rousing for oxygenation.

- Air Rousing for oxygenation and yeast dispersal.

Rouse if the start of fermentation is slow and up to 40 hours if the fermentation is slowing prematurely. If fermentation rate has to be corrected by unusual rousing check that the flavour of the resulting beer is not altered.

- In particular cases rousing with oxygen can be beneficial to sluggish fermentation.

- Time of skimming will depend on the formation of the yeast head and on gravity. The number of skimmings will affect the yeast count at rack

- Attemperators should be put on full flow after skimming to lower the temperature to stop fermentation and accelerate yeast sedimentation prior to racking.

Nevertheless if cooling is too fast the amount of yeast remaining may be inadequate to permit satisfactory secondary fermentation and/or fining action.

Measurement Protocols

- Saccharometer readings should be taken twice daily throughout fermentation and at the end of attemperation.

- pH of fermentation