Scroll to learn more about our history

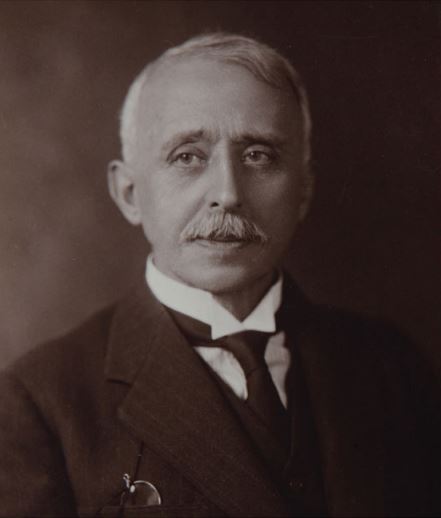

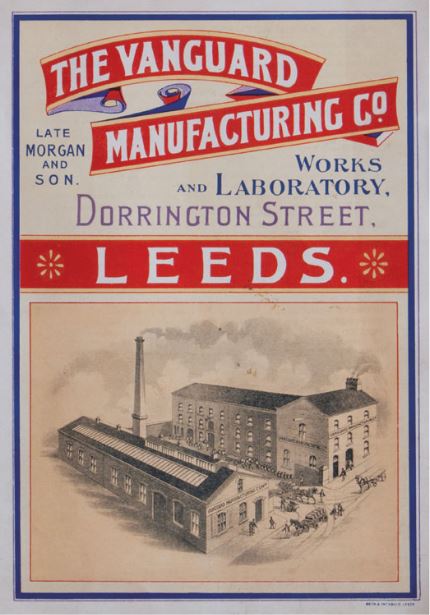

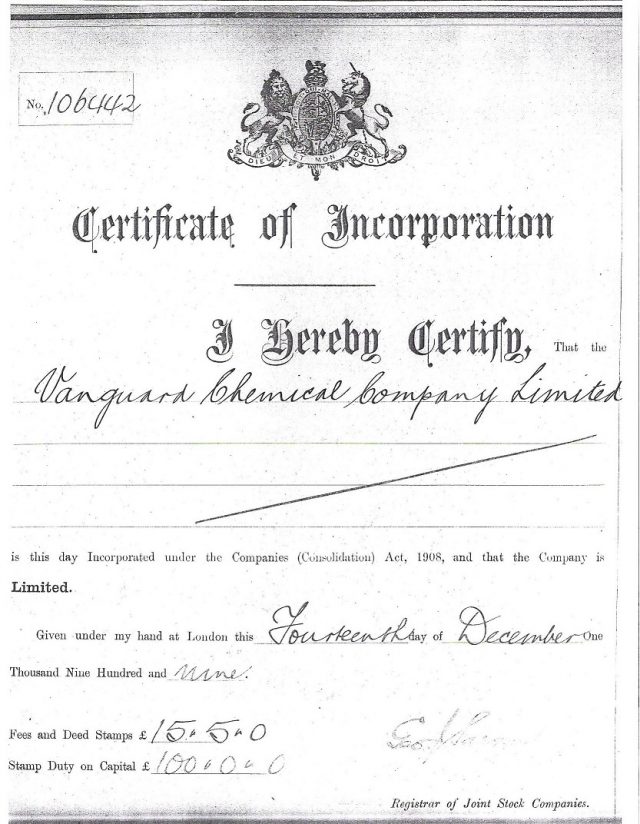

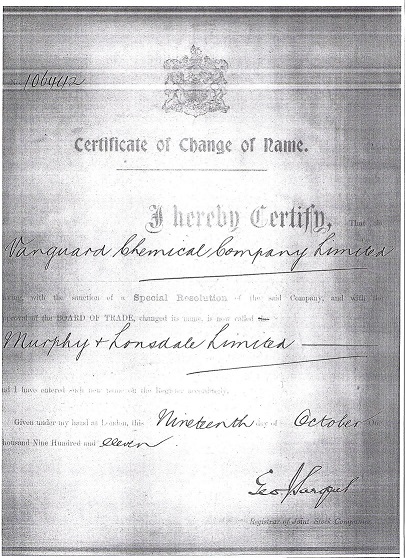

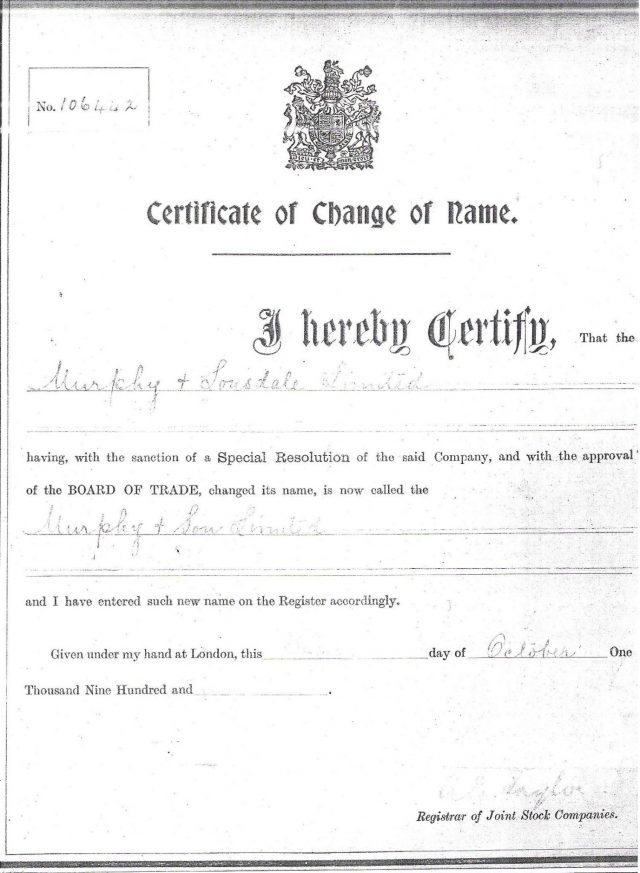

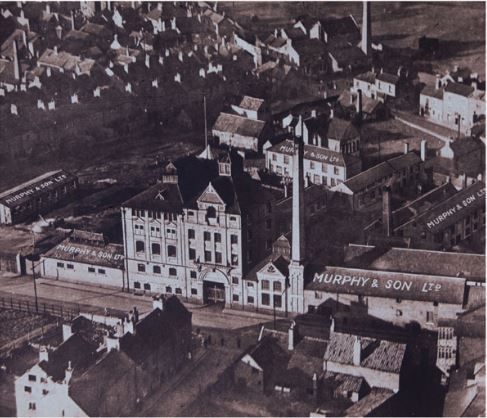

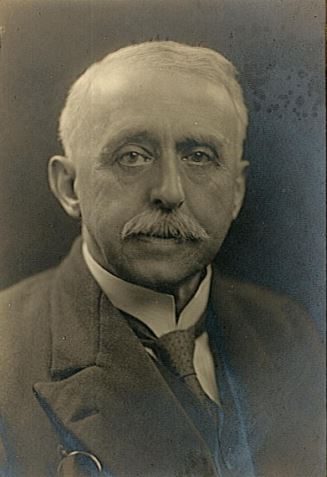

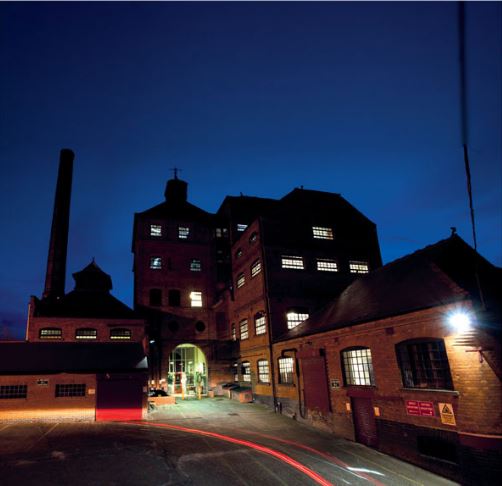

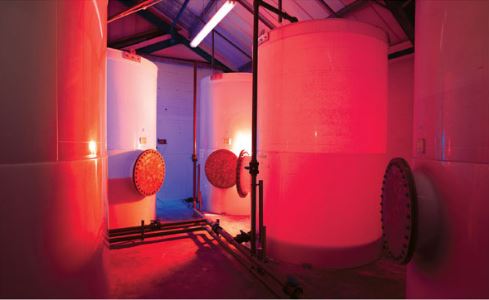

Mr Murphy set up and developed his chemical company at a time when the value of a scientific approach to brewing beer was in its infancy. Thus, our company Murphy & Son Ltd has been at the forefront of brewing innovation since 1887 and continues to evolve, advance and invent for the better of the industry.